What is a Prefabricated Steel Home and Why Are They Gaining Popularity

Prefabricated steel homes are increasingly becoming a popular choice for homeowners looking for innovative, sustainable, and cost-effective housing solutions. These homes are constructed off-site in a factory setting, allowing for greater precision in manufacturing and efficiency in the building process. As a result, prefabricated steel homes can be assembled on-site much faster than traditional homes, significantly reducing construction time and labor costs.

Moreover, the use of steel as a primary building material offers several advantages, including durability, resistance to pests, and lower maintenance requirements. With a growing emphasis on sustainability and eco-friendly construction practices, many people are turning to these homes for their renewable attributes. The modular designs also provide flexibility, allowing for various architectural styles that can cater to diverse aesthetic preferences.

As the trend of prefabricated steel homes continues to surge, it reflects a shift in consumer priorities towards efficient living, environmental responsibility, and modern design aesthetics. This introduction to prefabricated steel homes highlights not only their practical benefits but also their alignment with contemporary housing needs and lifestyle choices.

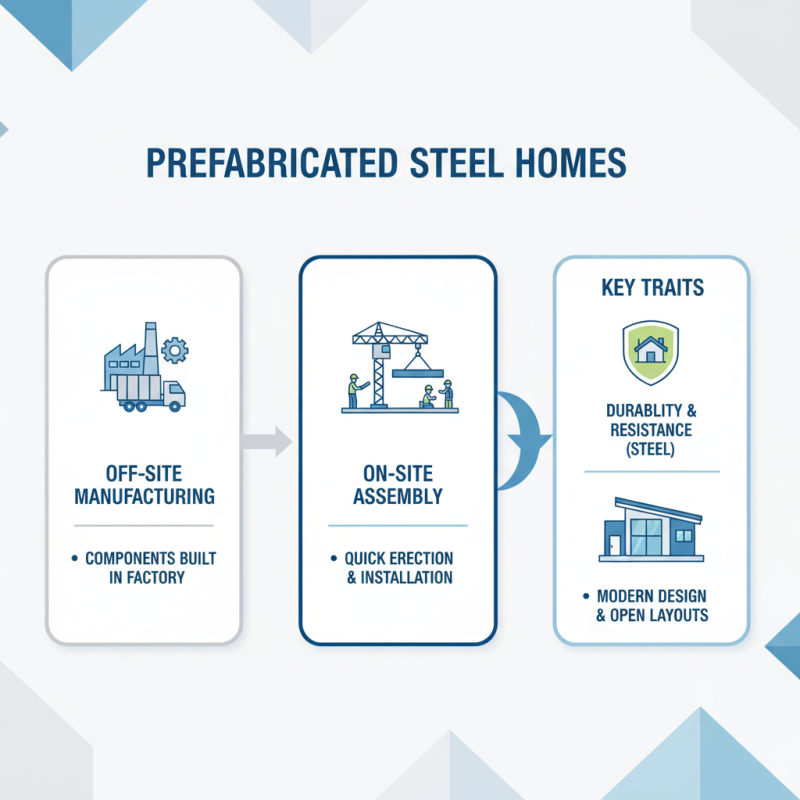

What Defines a Prefabricated Steel Home: Key Characteristics

Prefabricated steel homes are characterized by their construction method, where components are manufactured off-site and then assembled on-site. This innovative approach offers several key traits that set them apart from traditional building methods. Firstly, the use of steel brings durability and resistance to various environmental factors, providing a long-lasting solution for homeowners. Additionally, these homes often feature modern designs that appeal to contemporary tastes, with open layouts and large windows that enhance natural light.

Tips: When considering a prefabricated steel home, focus on energy efficiency. Many manufacturers offer designs that incorporate sustainable practices, such as energy-efficient insulation and solar panel options. This not only reduces your carbon footprint but can also lead to significant savings on utility bills.

Another defining characteristic of prefabricated steel homes is their speed of construction. Assembly is typically much faster than conventional methods, allowing families to move in sooner. This efficiency can be especially beneficial in areas facing housing shortages or for those needing a quick housing solution. Before choosing a prefabricated steel home, ensure you assess your local zoning regulations and land suitability to avoid potential complications during the building process.

The Benefits of Prefabricated Steel Homes: Cost Efficiency and Sustainability

Prefabricated steel homes are becoming increasingly popular due to their unique advantages, particularly in terms of cost efficiency and sustainability. One of the primary benefits of these homes is their swift construction process. Unlike traditional building methods, which can take months or even years, prefabricated homes are assembled from pre-manufactured components, allowing for a significant reduction in labor costs and construction time. This efficiency not only lowers the overall cost for homeowners but also minimizes financial strain during the building process.

Additionally, the sustainability of prefabricated steel homes is a compelling reason for their rising popularity. Steel is a durable and recyclable material, which means that these homes contribute to reducing waste and environmental impact. The manufacturing process for steel is also becoming increasingly energy-efficient, further enhancing the eco-friendliness of such homes. This aligns with the growing trend toward sustainable living, as more individuals seek housing solutions that not only meet their needs but also minimize their carbon footprint. As people become more environmentally conscious, the appeal of prefabricated steel homes continues to rise, presenting a smart and responsible choice for modern homeowners.

Industry Trends: Growth Statistics for Prefabricated Steel Homes

The prefabricated steel home market has seen significant growth in recent years, driven by a combination of economic factors, environmental considerations, and shifting consumer preferences. In 2022, the global market for prefabricated steel homes was valued at several billion dollars, with projections indicating a compound annual growth rate (CAGR) of over 5% through 2030. This upward trend is largely attributed to the increasing demand for affordable housing solutions and the efficiency of steel construction in meeting diverse architectural needs.

Moreover, the sustainability aspect associated with prefabricated steel homes plays a crucial role in their rising popularity. With an emphasis on reducing carbon footprints, steel is often regarded as a more sustainable building material compared to traditional lumber. Its recyclability and potential for energy-efficient designs resonate with environmentally conscious consumers. Additionally, the speed of construction and reduced waste during the building process make prefabricated steel homes an attractive option for builders and homeowners alike, further propelling their prevalence in the housing market.

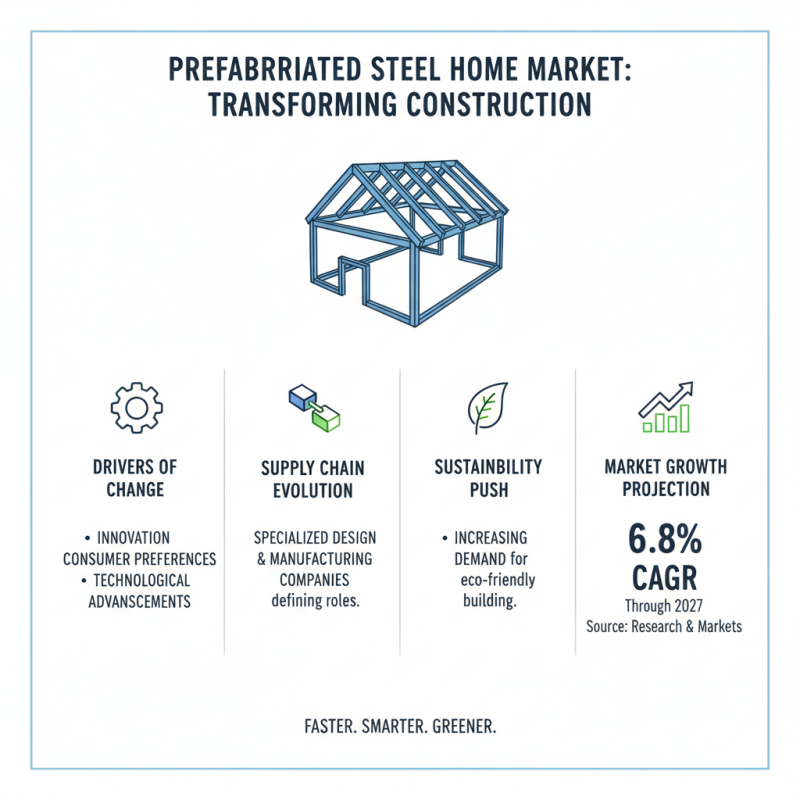

Key Supply Chain Players: Who is Leading the Prefabricated Steel Market?

The prefabricated steel home market is experiencing a significant transformation, driven by innovation and changing consumer preferences. Major supply chain players are carving out their roles in this evolving landscape, with many companies specializing in the design and manufacture of prefabricated steel structures. According to a recent market report by Research and Markets, the prefabricated construction market is expected to grow at a CAGR of 6.8% through 2027, largely propelled by advancements in technology and the increasing demand for sustainable building solutions.

Notably, supply chain leaders are adopting strategies that leverage cutting-edge technologies such as modular construction and AI-driven design processes. These innovations allow for reduced construction time and lower overall costs. Additionally, collaborations between manufacturers, architects, and suppliers are becoming more common, ensuring a streamlined process from production to installation. The focus on sustainability is also evident, as using steel in prefabricated homes helps meet eco-friendly building standards while reducing waste.

Tips: When considering a prefabricated steel home, it’s essential to evaluate local market players and their reputations. Conducting thorough research on suppliers’ past projects can provide insights into their reliability and quality. Additionally, understanding the supply chain dynamics can help you anticipate potential delays and budget more accurately for your construction project.

Comparative Analysis: Prefabricated Steel Homes vs. Traditional Construction Methods

Prefabricated steel homes are emerging as a popular alternative to traditional construction methods, primarily due to their efficiency and sustainability. Unlike conventional homes that rely heavily on on-site labor and extensive building materials, prefabricated steel homes are manufactured in a factory setting, where components are pre-made and then assembled on-site. This process significantly reduces construction time, minimizes waste, and often leads to lower overall costs. As resources become scarcer and environmental concerns mount, the steel prefab method presents a compelling option for eco-conscious homeowners.

In contrast to traditional construction, which can be impacted by weather delays and labor shortages, prefabricated homes benefit from consistent quality control and a more predictable timetable. Additionally, steel homes are known for their durability and strength, providing a longer lifespan and greater resistance to natural disasters compared to wooden structures. Beyond practicality, many consumers are drawn to the modern aesthetic and customizable designs that prefabricated steel homes offer, making them increasingly appealing in today's real estate market. As awareness around these benefits grows, so too does the acceptance and adoption of prefab steel homes as a viable alternative in the housing industry.

Comparative Analysis: Prefabricated Steel Homes vs. Traditional Construction Methods

Related Posts

-

Exploring the Benefits of Prefabricated Steel Homes: A Sustainable Living Solution

-

How to Build Steel Modular Homes in 2025 for Sustainable Living

-

The Ultimate Guide to Sustainable Living in Boxcar Homes

-

Top 10 Tips for Choosing Prefabricated Modular Homes for Your Dream Home

-

2025 Top Digital Trends Shaping the Future of Boxcar Homes and Sustainable Living

-

2025 How to Buy Manufactured Homes: Tips for First-Time Buyers